Bob's Mellor Mill Diary

Bob (Robert Humphrey-Taylor) is leading the excavations at Mellor Mill.

Copyright R H-T ©

If you want to volunteer to help get in touch via the contact us page.

By default Bob's Diary is displayed latest post first.

To go to the beginning and display in chronological order click here.

To switch back to the default of latest post first click here.

Now that Spring has arrived and our HLF funding is about to come on line we are looking to increase our activity down at Mellor Mill. There are a number of tasks, which do not involve excavating on your hands and knees, which need to be done and we are looking for volunteers to help out. Can you spend a few hours at weekends making a contribution to this locally important project?

Tasks which immediately need addressing include:

1, Strimming of undergrowth around the main mill area

2. Cutting of ivy growth around trees

3. Additional guides to show visitors around the site

4. Pathway preparation

5. Clearing an area ready for temporary toilets and welfare cabin

6. Recording and bagging of finds

7. Topographic survey of remains uncovered so far

Appropriate training will be given to enable you to carry out these tasks. All equipment supplied.

If you are able to offer some time for any of the above then please contact me either by email

Of course, we are always ready to welcome volunteers who want to be involved in the archaeological dig as well.

Bob

- Details

- Category: Bob's Diary

- Hits: 11576

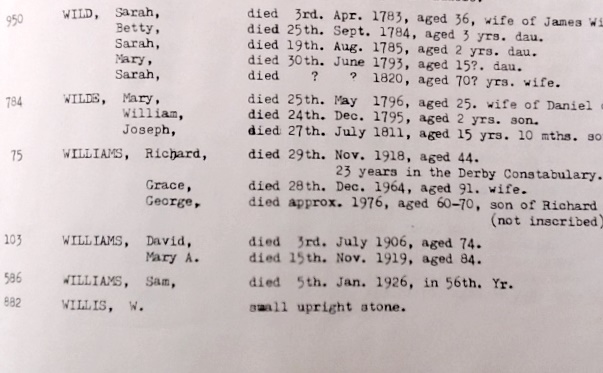

Rachel Miller recently made contact, via Facebook, with a lady from Glossop whose Great, great, grandfather was an overseer at Mellor Mill. As a result, Rachel and I went to visit the Great great, granddaughter at her house. She told us a story about her family research which had led her to William Willis. William along with his wife, Charlotte and their children, lived on Royal Oak Row and more specifically the cottage immediately to the right of the pub. He was an overseer at Mellor Mill having worked his way through the system from being an apprentice brought up from London and possibly a Clerkenwell Orphan. Rachel and I went to search for a possible grave for William Willis at Mellor Church. My first stop was to ask Ann Hearle if I could borrow the transcripts of the grave at Mellor Church, (below). A quick search shows that there is a simple small stone,(above) in the graveyard, marked W Willis. I think it is reasonable to believe this is the same man.

- Details

- Category: Bob's Diary

- Hits: 11841

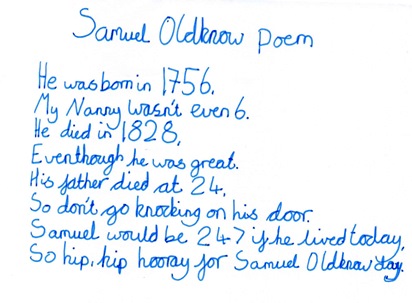

Following my visit to Rivington Primary School, which was Samuel Oldknow’s Grammar School, I received the letters and drawings from the pupils and staff.

Following my visit to Rivington Primary School, which was Samuel Oldknow’s Grammar School, I received the letters and drawings from the pupils and staff.

Samuel Odknow visits his father's grave. The inscription on the gravestone reads:

gravestone reads:

"Here lieth the Body of Samuel Oldknow of Nottingham late of Anderton who departed this life Aug 7th 1759 Aged 25 yrs Likewise Eliz. his daughter who died March 12th 1762 Aged 4 years."

He lived at Roscoe Low Farm, Anderton and was reputedly the first man in England to manufacture muslin, a fine cotton having previously been woven in the East. He came to the district in 1754, and married and prospered, leaving a son Samuel who worked with Richard Arkwright near Stockport. According to John Rawlinson, however, muslin was first produced by the widow of Samuel the elder, and a partner in the business, in 1764. Samuel Oldknow's mother Margaret after becoming a widow married for the second time to a farmer, John Clayton with whom she had three children Margery, Samuel and John.

For the pdf file of the letters and paintings from the children and staff, of the school, click on picture below.

- Details

- Category: Bob's Diary

- Hits: 11977

We are back after three weeks break over Christmas and the New Year.The morning started off very wet and cold but as the day progressed the rain stopped and even the sun put in a brief appearance.We can now boast having an "International Staff" at the Mellor Mill dig. We have been joined by Lara Ramperez (on the right in the photograph). Lara is a qualified Archaeologist from Spain.Currently living in Manchester and keen to be involved in our project. Today Lara and Rachel can be seen working on excavating the foundations of the second Lancashire Boiler.

- Details

- Category: Bob's Diary

- Hits: 11362