All Steamed Up at Mellor Mill...........................

We are in that pregnant pause between the submission of our bid to The Heritage Lottery Fund and the panel’s decision.

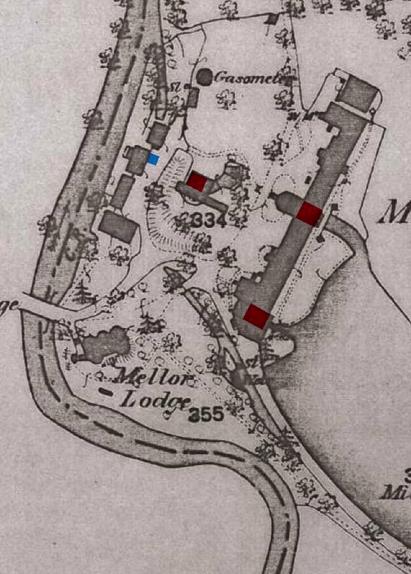

The project has been running, on limited resources, for two years and we have built up a ‘head of steam’ which we don’t want to lose. Our volunteers have been stoical in their toils to identify all the buildings and features at the Mellor Mill site in order for a definitive survey to be carried out as part of the HLF Stage 2 submission. The survey completed and our bid safely deposited with HLF we were determined that we would carry on with the excavations as if the HLF award had been made.

At the end of July we found ourselves starting to excavate at the northern extremity of the main Mill complex.This is the boiler house and the steam engine house. A building, constructed in 1860, which is detached from the main Mill, housed the Lancashire Boiler and two horizontal steam engines, manufactured by Goodfellows of Hyde. We started to investigate the depression where the building once stood but now was only showing the top few inches of the long engine holding down bolts above the debris and dense undergrowth.

Early on we uncovered what, at first, was thought to be the boiler flue but this seemed to be in the wrong location. The latest interpretation is that it is an economizer providing pre-heated water to the boilers to save on fuel.

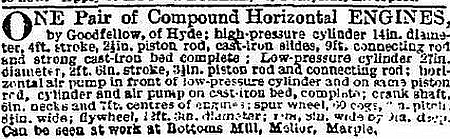

In 1877 we find the original steam engines put up for sale and the following is the sale notice from the Manchester Guardian

Manchester Guardian1877 Dec 18 p7

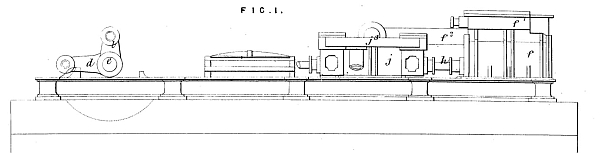

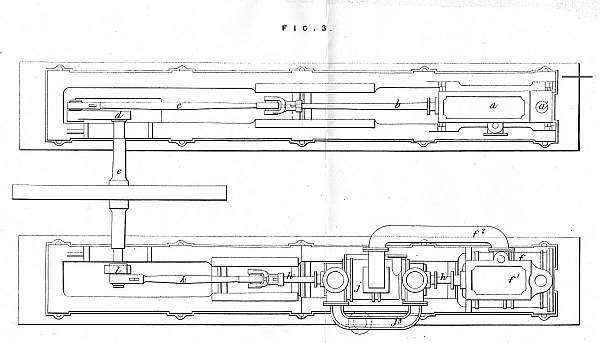

ONE Pair of Compound Horizontal ENGINES, by Goodfellow, of Hyde; high-pressure cylinder 14in.diameter , 4ft. stroke, 2½in. piston rod, cast-iron slides,9ft. connecting rod and strong cast-iron bed complete; low-pressure cylinder 27in.diameter, 2ft. 6in. Stroke, 3½in. piston rod and connecting rod; horizontal air pump in front of low-pressure cylinder and on same piston rod, cylinder and air pump on cast-iron bed, complete; crank shaft,6in. necks and 7ft. centres of engines; spur wheel, 60 cogs, 3in. pitch,8¼in. wide; flywheel, 12ft.3in. diameter; rim, 8in. wide by 9in. deep.Can be seen at work at Bottoms Mill, Mellor, Marple.

From measurements taken from the holding down bolts, protruding through the ashlar engine mounting blocks, it has been calculated that the original pair of engines were replaced with a much more powerful pair in 1877. Possibly capable of producing 120 hp which is equivalent in power to the three mill water wheels. Was this a last ditch attempt to keep up with the steam powered mills in Stockport, Manchester and beyond? The new engines were powered by not one but two Lancashire Boilers with the second one housed in an extension to the north of the boiler house with extensive alterations to the coal cellars taking place at the same time.

During the excavations there have been a number of significant finds.

We have recovered several pieces of ‘fire bar’ from the boiler house and from the engine fly wheel pit a tapered key which was possibly to join a connecting rod to a piston.

From Goodfellow Patent 1858 No 2387

A group of Scouts from Warrington, working towards their Heritage Badge, and later ‘A’ level Archaeology students from Aquinas College, in Stockport, have uncovered a substantial section of the flue which ran up the hillside from the boiler house.

Section of the brick arched flue.

A view across the engine house to the right and the boiler house to the left. The vertical section of brick wall separates one from the other. The fly wheel pit can be clearly seen in the engine house with the holding down bolts for the engines to either side.

We are sure that there has to be a drainage system from the boiler house to allow for the boilers being drained down for maintenance. To date we have failed to find its exact location and so during inclement weather we suffer from a build up of water at the bottom of the dig.

The building has been difficult, at times, to interpret due to the major alterations and extensions which took place when the engines and boilers were upgraded and we will need to give careful consideration to which features to present for public viewing. Of major concern is the conservation of the exposed masonry and its protection from the elements in the future. The English Heritage, Heritage at Risk team, will be advising us on the best way forward to ensure this important piece of our Industrial Heritage is presented and protected for all to enjoy into the future.

Weather permitting, work will carry on through the winter. Visitors and Volunteers are always welcome. We have tour guides available both for the casual visitor and, by arrangement, for organized groups. Further information is available from Mellor Archaeological Trust via our contact page.

(all photos in this diary entry copyright Bob H-T)